1994

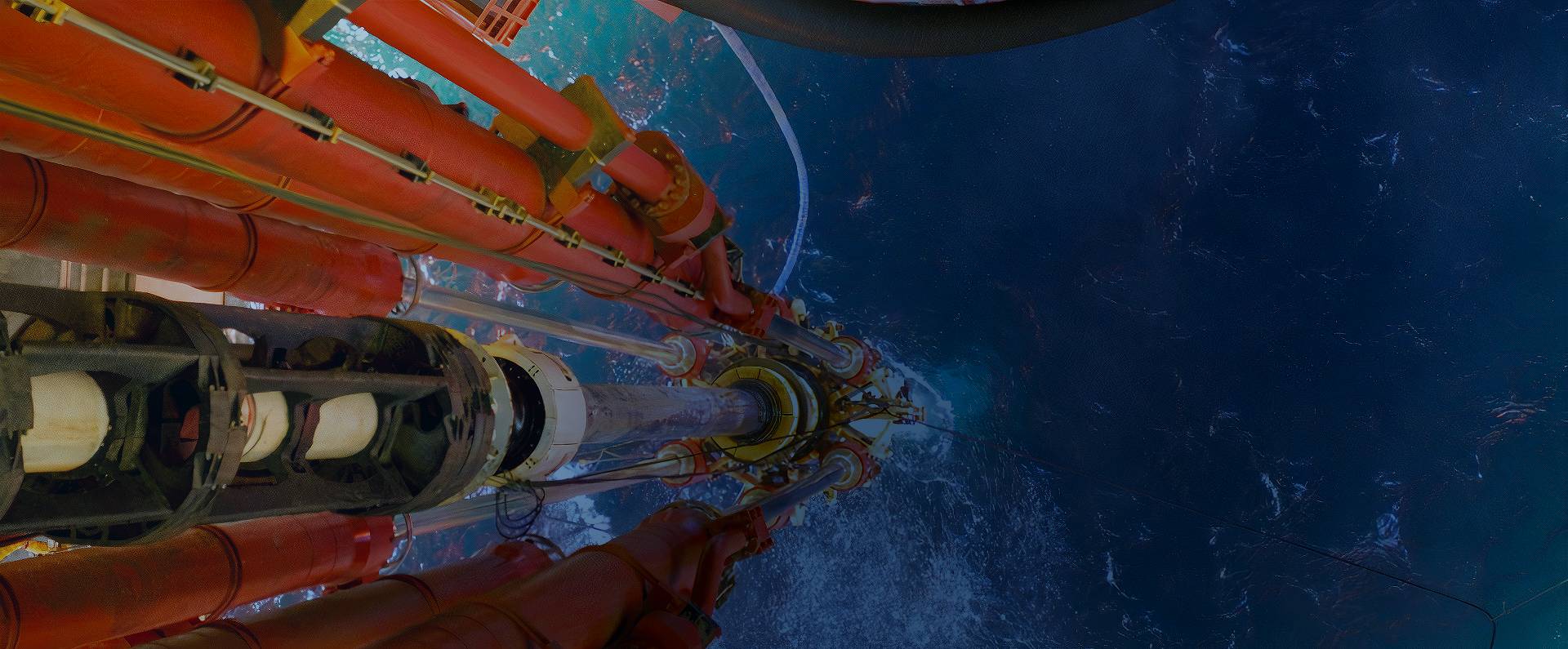

Norkram is born from the idea to clean and reuse Thread Protectors returned from off-shore rig sites

1998

Norkram outgrows it’s warehouse and storage area in Newburgh, and moves to Longside Airfield Industrial Estate in Peterhead—8000m2 of outdoor storage and 1000m2 of workshop space

2000

The Norkram Semi Automatic Cleaning Machine is designed, built, and installed to increase production to meet customer demand

2002

A shredder is introduced alongside a guillotine to aid the recycling process further adding to Norkram’s green credentials

2002

Later in the year to increase speed & efficiency in the recycling process, a granulator was added to the arsenal of machinery to allow 25mm shred to be further reduced to regrind

2003

Norkram grows the team continuously and gains customers, selling to overseas locations as well as the North Sea

2006

Increasing the team further, Norkram employs a full time sales manager to maximise potential

2012

After increasing sales steadily, Norkram invested in an extruder for pelletising to complete the recycling process

2013

Further developing capabilities, Norkram designed and built machinery for the manufacture of bumper rings from extruded recycled plastic. These are now sold to pipe mills around the world

2016 - Present

Working with a local engineering company, Norkram designed and built the Norkram Pipe Lifting System for the safe movement of pipe. This is a DNV approved lifting system which has been manufactured for sale or rental. When our engineering partner decided to sell their company, Norkram decided to purchased Taylor and Son Engineering which has allowed us to expand our product range as below:

Norkram Flexi-Lance – Automatic internal pipe cleaning and drifting

Norkram Wire Brushing and Coating Unit – Rejuvinate the OD of pipe by removing scale and rust, and adding a quick cure UV coating

Pipe Handling Systems for machine shops and inspection halls

FUTURE

Norkram continues to come up with innovative solutions to improve business and expand further into green initiatives for the future of the business, whilst contributing to the circular economy in scotland